Ride On Skid Steer DBL-T750

DIG-BOY DBL-T750 stand-on loader leads its class in lift height and reach. Dominate any job site with a low total cost of ownership.

DBL-T750

Ride On Mini Track Loader

Are you tired of walk-behind loaders that are slow, weak, and exhausting to use? Are you struggling with machines that can’t lift high enough to load a truck or handle a full pallet of materials?

This isn’t just inefficient; it’s limiting your growth. You’re forced to do things in two steps instead of one, wasting precious time. You’re turning down more profitable, heavy-lifting jobs because your current equipment simply can’t handle the weight.

Step up to the DIG-BOY DBL-T750 heavy duty stand-on track loader. This is more than a loader; it’s a serious piece of professional equipment. Because it boasts an impressive 1,300-kg rated operating capacity and best-in-class lift height, so you can load dump trucks in a single motion and move heavy pallets with ease. The smooth pilot controls and premium ride-on platform make every job faster and easier.

DBL-T750: Class-Leading Specs

Key Specifications

| Rated Loading Capacity | 400KG |

| Machine Weight | 1330kg |

| Working System Pressure | 250 bar |

| Working System Flow Rate | 62.4 L/min |

Engine

Dimension

| Overall length | 2,694 mm/106.06in |

| Overall width | 1,070 mm/42.13in |

| Overall height | 1,520 mm/59.84in |

Other Parameters

| Driving System Pressure | 250 bar |

| Driving System Flow Rate | 62.4 L/min |

| Work Pressure | 18mpa |

| Walking Speed | 6km/h |

| Operating Height | 2,695mm/106.1 |

| Height to Bucket Hinge Pin | 2,175mm/85.63in |

| Overall Length without Bucket | 2,067mm/81.38in |

| Angle of Departure | 23° |

Engineered for Maximum Productivity

Integrated Ride-On Platform ->

Command Your Job Site:

The integrated ride-on platform keeps you above the surface conditions. It provides a wider view to the sides, as well as to the bucket cutting edge.

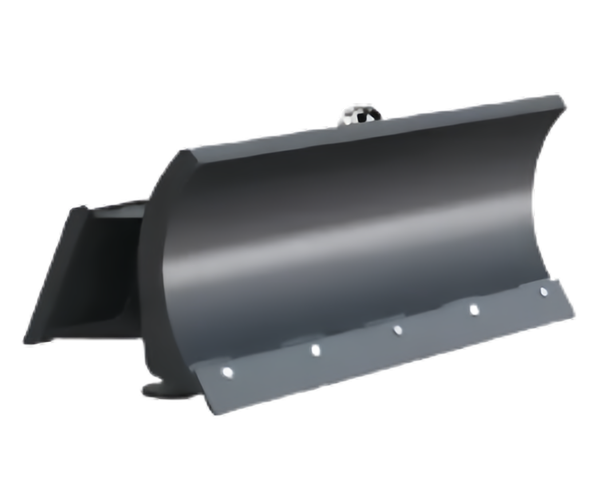

Attachment Interfaces ->

A Universe of Capabilities:

Two attachment interfaces help you make quick work of grading, backfilling, digging holes, hauling and loading materials, and other tasks.

Durable Exterior Panels ->

Built for the Real World:

The body’s exterior panels are made from high-strength steel. This ensures maximum strength and durability while providing excellent component protection.

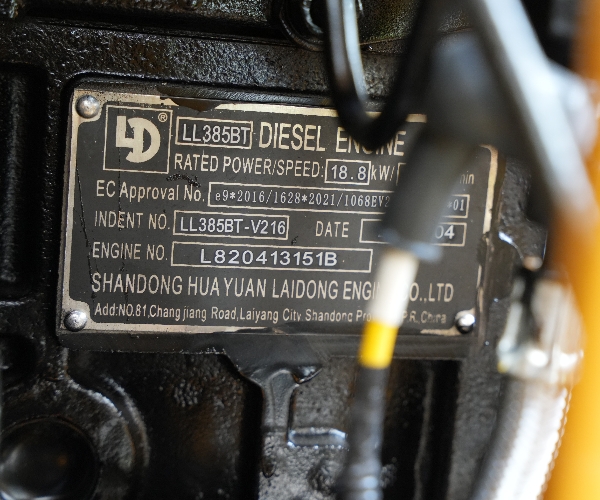

Powerful Engine ->

Power Without Complication:

You’ll experience greater performance with the DIG-BOY DBL-T750. Powered by a high-torque, non-DPF engine, it delivers plenty of muscle to get the job done. A new, direct-drive system also eliminates belts for less maintenance and more uptime.

Sealed Rollers ->

Less Maintenance, More Profit:

Permanently lubricated (sealed) rollers and idlers reduce undercarriage maintenance and leave more time for your job site tasks. The DIG-BOY DBL-T750 also features maintenance-free bushings in the work group, which support increased uptime and lower your operating costs.

Your All-in-One Business Solution

As a mini skid steer supplier from China, we understand your need for attachments. Our mini skid steers come equipped with a quick-change system.

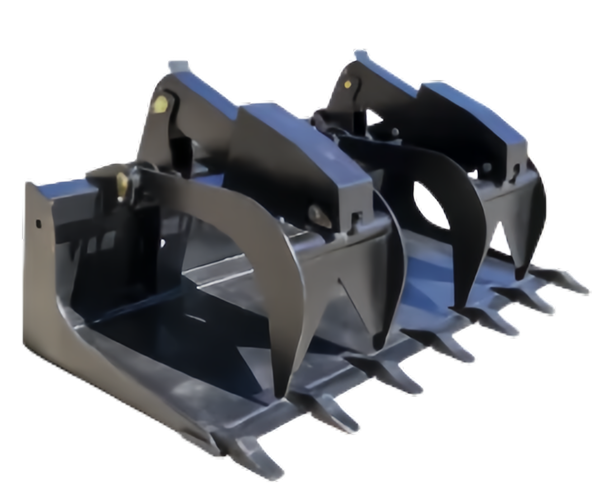

Skid Steer Grapple

Lift and move loose materials such as manure, bedding, and hay.

Pallet Fork

Move bulky, bagged or palletized material quickly and easily.

Grapple

Attachment with the brute force and agility to get the tough jobs done.

Hydraulic Hammer

attachment with the brute forceand agility to get the tough jobsdone.

Angle Broom

Clear away dirt, dried mud, lightsnow and other debris.

Ride On Mini Skid Steer

DIG-BOY is a trusted and reliable heavy duty stand-on track loader manufacturer, engineering equipment for the construction, agricultural, forestry, and landscaping industries. It’s our core belief that no matter what site you’re working on—or its condition—you should be able to complete the task at hand quickly and with ease. That’s why we make machines that help you get more done in more places than you ever thought possible.

Today, our global team of over 300 professionals designs, engineers, and builds our equipment not only to be different, but to be the best. We are relentlessly focused on delivering the most durable and high-performing machines that provide an unbeatable return on your investment, backed by over 20 years of industry expertise.

A Global Supplier with Customized Solutions

DIG-BOY compact machines are popular and trusted in the global market. So far, we have successfully exported our equipment to Southeast Asia, America, Europe, and the Middle East, proving our capability to meet diverse international standards and regulations. Our extensive experience in global logistics ensures a smooth, reliable delivery process.

We understand that every market is unique. We can customize new models based on your specific customer needs and market preferences. Currently, we offer a wide range of options for renowned engine brands (like Kubota, Perkins, Yanmar), cabin types, drive systems, dozens of specialized attachments, and even custom machine colors to give your business a competitive edge.

Explore Our Full Range of Loaders

Your Stand-On Loader Questions, Answered

Better visibility and agility. The 360-degree view from the standing platform is unmatched for safety in tight spaces. It's also faster to hop on and off for quick tasks.

Peace of mind. It protects your investment from unexpected repair costs. We stand behind our quality, so you can buy with confidence.

It's a critical safety feature. It locks the controls to prevent accidental movement when you're getting on or off the machine.

Absolutely. Our loaders are designed to be versatile. You can expand your services and profitability by adding new attachments at any time as your business grows.

It can handle a full pallet of pavers (approx. 1,000 lbs) or a large bale of hay. This heavy-lifting capability means you can handle commercial-grade tasks, not just small residential jobs, opening up more profitable work.